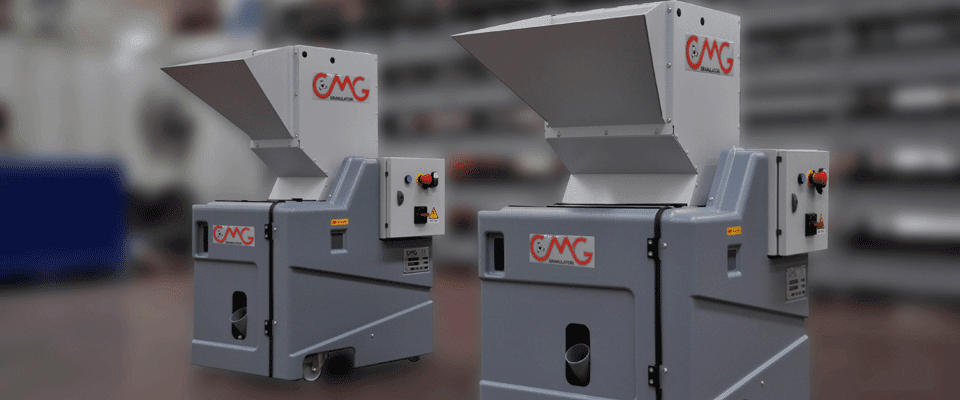

TESTRON granulators for products deriving from injection moulding processes. This is technologically advanced equipment capable of meeting all scrap recovery requirements.

During the injection moulding process, plastic first undergoes a casting process and is then injected in a closed, high pressure mould. After it cools, this transformation creates the finished product.

This process implements a high variety of finished products, from techno polymers and other thermoplastic resins, the most common of which are:

- Polymer chlorides (PVC)

- Polyolefins (PE, PP)v

- Polyether imide (PEI)

- Polysulfones (PSU)

- Polycarbonates (PC)

- Polyamides (PA 6, PA 66, PA 11, PA 12, PAMXD 6, PA 63T)

- Acetal resins (POM)

- Polyesters (PET, PBT)

- Polyphenyl sulphur (PPS)

- Styrolic resins (MBS, MABS, ABS, SAN, PS)

- Acrylic resins (PMMA)

- Polyphenol oxidase (PPO)

TREATED MATERIALS

The task of transforming scrap coming from injection moulding into granules is entrusted to granulators and shredders capable of reducing the following products:

- Sprues

- Plastic material processing scrap and swarf

APPLICATIONS AREAS

The main application sectors are:

- Automotive industry

- Packaging

- Construction

- Optics

- Cosmetics

- Biomedicals

- Electronics

- Electric equipment industry

Contact our team to learn more about our machines and services info@testrongroup.com